Table of Contents:

- Introduction

- The Role of Vacuum Pumps in Automotive Manufacturing

- Types of Vacuum Pumps Used in Automotive Manufacturing

- Applications of Vacuum Pumps in the Automotive Industry

- Benefits of Using Vacuum Pumps in Automotive Manufacturing

- Challenges and Considerations

- Future Trends in Vacuum Pumps for Automotive Manufacturing

- Conclusion

Introduction

In the ever-evolving world of automotive manufacturing, driving efficiency is paramount. One unsung hero in this domain is the vacuum pump. Vacuum pumps in automotive manufacturing play a critical role in ensuring that various processes are efficient, cost-effective, and of high quality. This blog delves into how these vital components contribute to the automotive industry.

The Role of Vacuum Pumps in Automotive Manufacturing

Vacuum pumps are indispensable in automotive manufacturing. They serve multiple functions, from maintaining brake systems to controlling emissions and forming parts. By creating a partial vacuum, these pumps facilitate processes that are otherwise challenging or impossible, thus driving efficiency in automotive manufacturing.

Types of Vacuum Pumps Used in Automotive Manufacturing

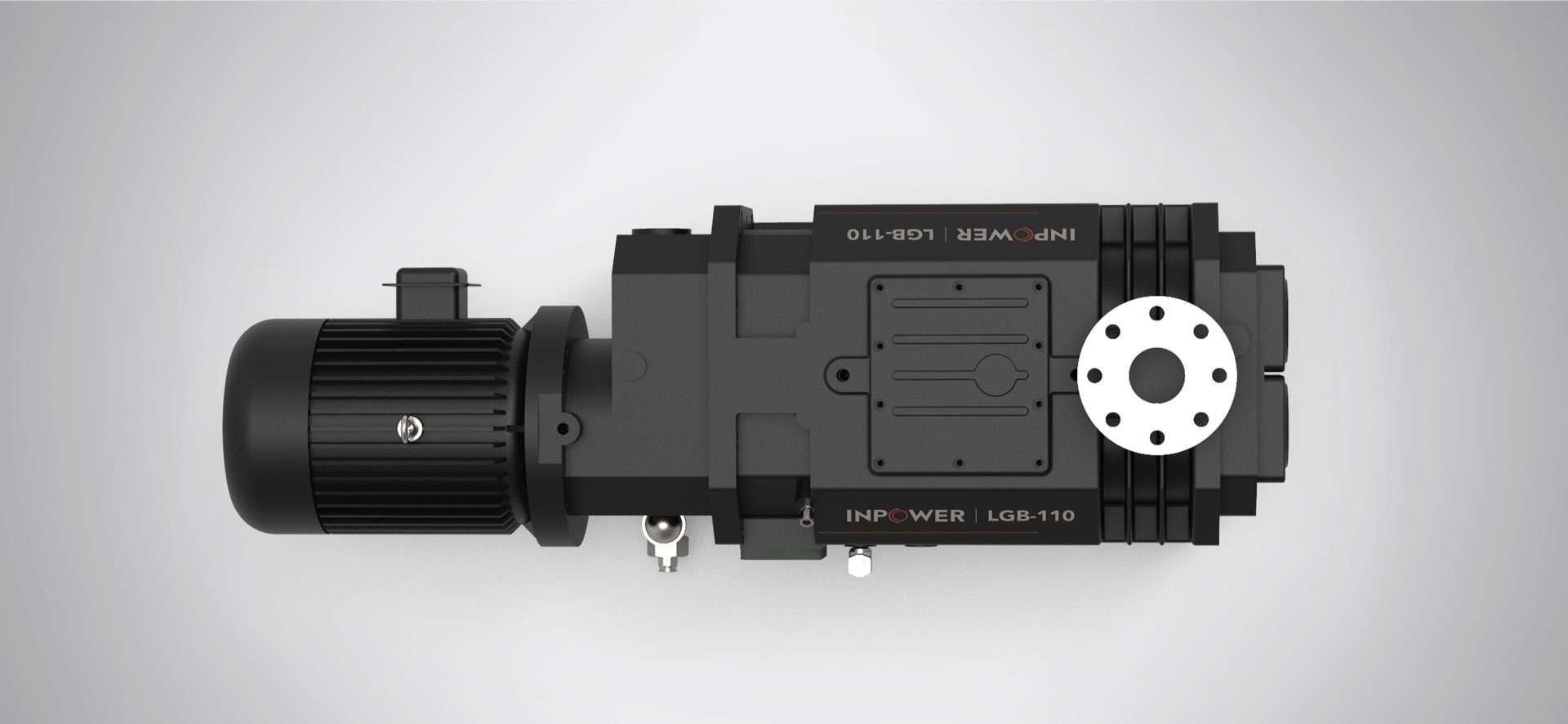

Rotary Vane Pumps

Rotary vane pumps are commonly used in the automotive industry due to their reliability and efficiency. These pumps operate by using a rotary mechanism with vanes that move in and out of slots to seal against a chamber and create a vacuum.

Diaphragm Pumps

Diaphragm pumps are known for their durability and are used in applications requiring chemical resistance. They use a diaphragm to move gases, making them ideal for handling aggressive or corrosive gases in the manufacturing process.

Screw Pumps

Screw pumps are another popular type used in automotive manufacturing. They operate by using two screw rotors to create a vacuum. These pumps are valued for their ability to handle large volumes of gas and their efficient operation at high throughputs.

Applications of Vacuum Pumps in the Automotive Industry

Brake Systems

One of the most critical applications of vacuum pumps in automobiles is in brake systems. Vacuum pumps ensure that brake systems have the necessary vacuum pressure to function effectively. This is particularly important in diesel and turbocharged engines, where the natural vacuum pressure may be insufficient.

Emission Control

Vacuum pumps play a vital role in emission control systems by providing the vacuum needed to operate various emission control devices. This helps in reducing the environmental impact of vehicles, making the manufacturing process more sustainable.

Vacuum Forming

Vacuum forming is a process wherein a sheet of plastic is heated until pliable and then formed into a specific shape using a vacuum. This technique is widely used in automotive manufacturing to create various parts, including dashboard panels and interior components.

Benefits of Using Vacuum Pumps in Automotive Manufacturing

Enhanced Efficiency

Using vacuum pumps in automotive manufacturing significantly enhances efficiency. These pumps streamline various processes, reducing the time and effort required to achieve desired results.

Cost Savings

Vacuum pumps contribute to cost savings by reducing waste and increasing the speed and precision of manufacturing processes. This leads to lower operational costs and increased profitability.

Quality Improvement

Vacuum pumps improve the quality of automotive parts by ensuring precise and consistent manufacturing conditions. This results in higher-quality end products that meet or exceed industry standards.

Challenges and Considerations

Maintenance Requirements

While vacuum pumps offer numerous benefits, they also come with maintenance requirements. Regular maintenance is essential to keep the pumps operating efficiently and to prevent costly downtime.

Selecting the Right Pump

Choosing the right vacuum pump for a specific application is crucial. Factors such as the type of gas handled, the required vacuum level, and the desired throughput must be considered to ensure optimal performance.

Future Trends in Vacuum Pumps for Automotive Manufacturing

The future of vacuum pumps in automotive manufacturing looks promising, with advancements in technology leading to more efficient and eco-friendly options. Innovations such as electrically driven vacuum pumps and smart monitoring systems are expected to revolutionize this industry.

Conclusion

In summary, vacuum pumps are integral to driving efficiency in automotive manufacturing. They enhance process efficiency, reduce costs, and improve quality. By understanding their role and benefits, manufacturers can make informed decisions that contribute to the overall success of their operations.

0 Comments